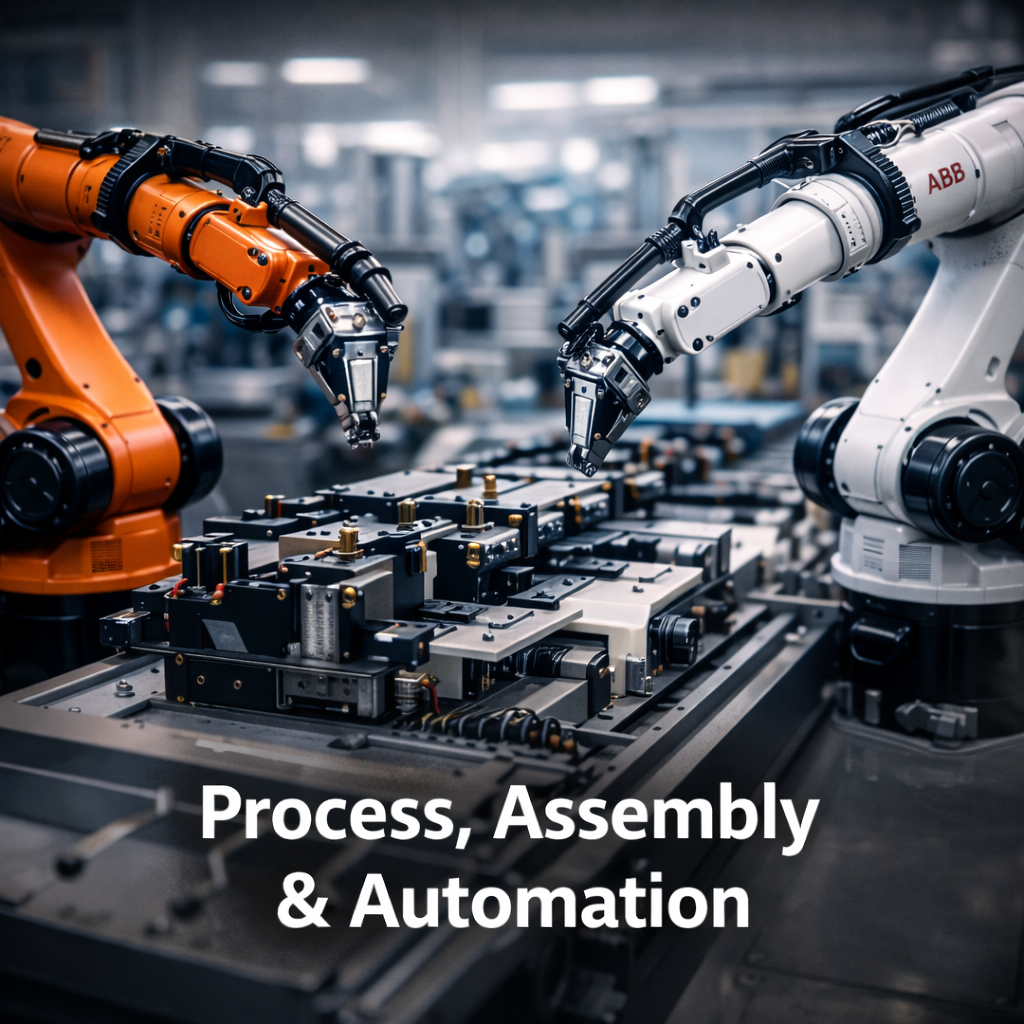

What We Take Responsibility For

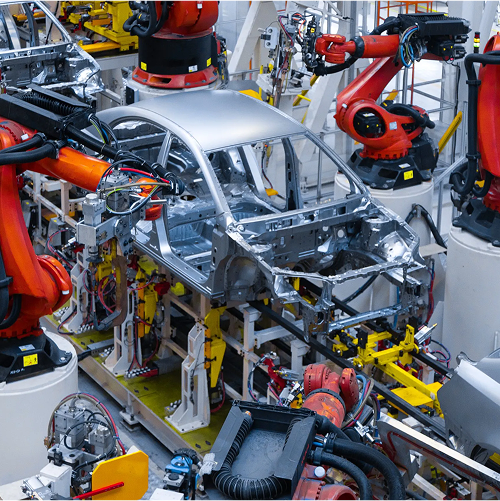

Plant Setup (Greenfield & Brownfield)

From empty floor to stable production.

Plant setup decisions define performance for years. Poor layouts, rushed capacity planning, and fragmented execution create permanent inefficiencies.

Mecwerx provides end-to-end plant setup support, owning engineering and execution from concept to stable operations.

What Plant Setup Support Means

Plant setup is not consulting.

It is engineering + execution + accountability.

We convert business intent into a working production system and stay responsible until output is stable.

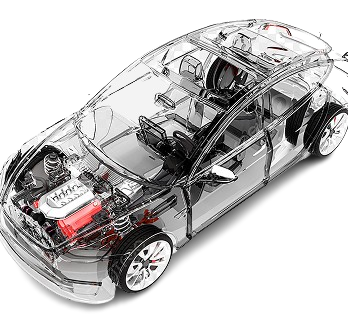

Scope of Plant Setup

Planning & Engineering

Capacity and throughput definition · Process flow and layout planning · Space utilisation and expansion readiness · Manpower and workflow alignment

System Execution

Production lines and workstations · Custom machines, SPMs, tooling and fixtures · Material flow and storage systems

Installation & Commissioning

Installation sequencing and coordination · Dry runs, trials and ramp-up

Readiness & Training

SOPs and documentation · Operator, supervisor and maintenance training

Greenfield & Brownfield

Greenfield

Right-first setup from a bare floor · Faster startup with disciplined ramp-up

Brownfield

Capacity expansion without disrupting operations · Bottleneck removal and line re-engineering